Soil Compaction in Agricultural Production

Mark Jeschke, Ph.D.1 and Nanticha Lutt2

My Account

Mark Jeschke, Ph.D.1 and Nanticha Lutt2

Soil compaction is one of the most serious forms of soil degradation caused by agricultural production. However, unlike other forms of soil degradation, such as erosion or salinization, compaction is often difficult to detect and measure and can limit crop growth and yield without presenting any obvious symptoms. When symptoms are present, such as stunted crop growth, nutrient deficiency, or poor water infiltration, they may be attributed to other causes.

In general, compaction issues in crop production are becoming more prevalent. The size and weight of farm machinery has increased dramatically over the past several decades as farm operations have gotten larger and machines need to cover more acres. Earlier planting of corn to maximize yield can increase the likelihood of working fields in which portions of the field are too wet. Additionally, farm operations covering larger acreages spread over greater areas may come under greater pressure to operate in too-wet conditions, exacerbating the problem of compaction.

Figure 1. Corn seedling that has failed to emerge due to prolonged cold stress and compacted soil conditions. The coleoptile was unable to push upward to the soil surface and is twisted and malformed as a result.

Some degree of soil compaction is the inevitable consequence of modern crop production due to the need to move machinery through the field to plant, manage, and harvest a crop. Soil compaction likely cannot be eliminated entirely from modern agricultural systems, so it must be managed and minimized to the extent possible.

Soil compaction is defined as the increase in bulk density and corresponding decrease in porosity of soil caused by loads applied to it. Soil compaction can have numerous negative effects on crop production, including restriction of root growth and reduced water-holding capacity. Highly productive, well-aggregated, agricultural soils tend to consist of about 50% solids and about 50% pore space with an equal distribution of macropores and micropores in this pore space (Brady, 1990). This ratio of macropores to micropores allows soil to store ample water for plant growth while allowing for gaseous exchange in the soil profile to provide oxygen to plant roots. Soil minerals have a particle density of about 2.65 g/cm3, so a medium textured soil consisting of 50% pore volume will have a bulk density near 1.33 g/cm3 (USDA-NRCS 2008).

Normal Soil

Compacted Soil

Figure 2. Characteristics of normal and compacted soils. (Adapted from Wolkowski, 2010).

Finely textured soil and soil high in organic matter have lower bulk density, whereas sandy soils have less pore space and consequently have a higher bulk density. The range of bulk density that is favorable for plant growth differs based on soil texture, as does bulk density that is restrictive to plant growth (Table 1).

Table 1. General relationship of soil bulk density to root growth based on soil texture (USDA-NRCS, 2008).

Soil Texture |

Ideal Bulk Density for Plant Growth |

Bulk Density that Restricts Root Growth |

|

g/cm3 |

g/cm3 |

Sandy |

< 1.60 |

> 1.80 |

Silty |

< 1.40 |

> 1.65 |

Clayey |

< 1.10 |

> 1.47 |

Soil compaction that negatively impacts crop growth can occur in a number of different ways and at different depths in the soil profile. Surface compaction from heavy rains, sidewall compaction from wet conditions at planting, and hard pans at the bottom of the plow layer can all restrict root growth and reduce crop yield. From a management perspective, however; the most serious form of compaction is that caused by wheel loads from machinery operating in the field. Compaction caused by heavy axle loads can extend from the soil surface down into the subsoil where it can persist for years and is difficult or impossible to remediate.

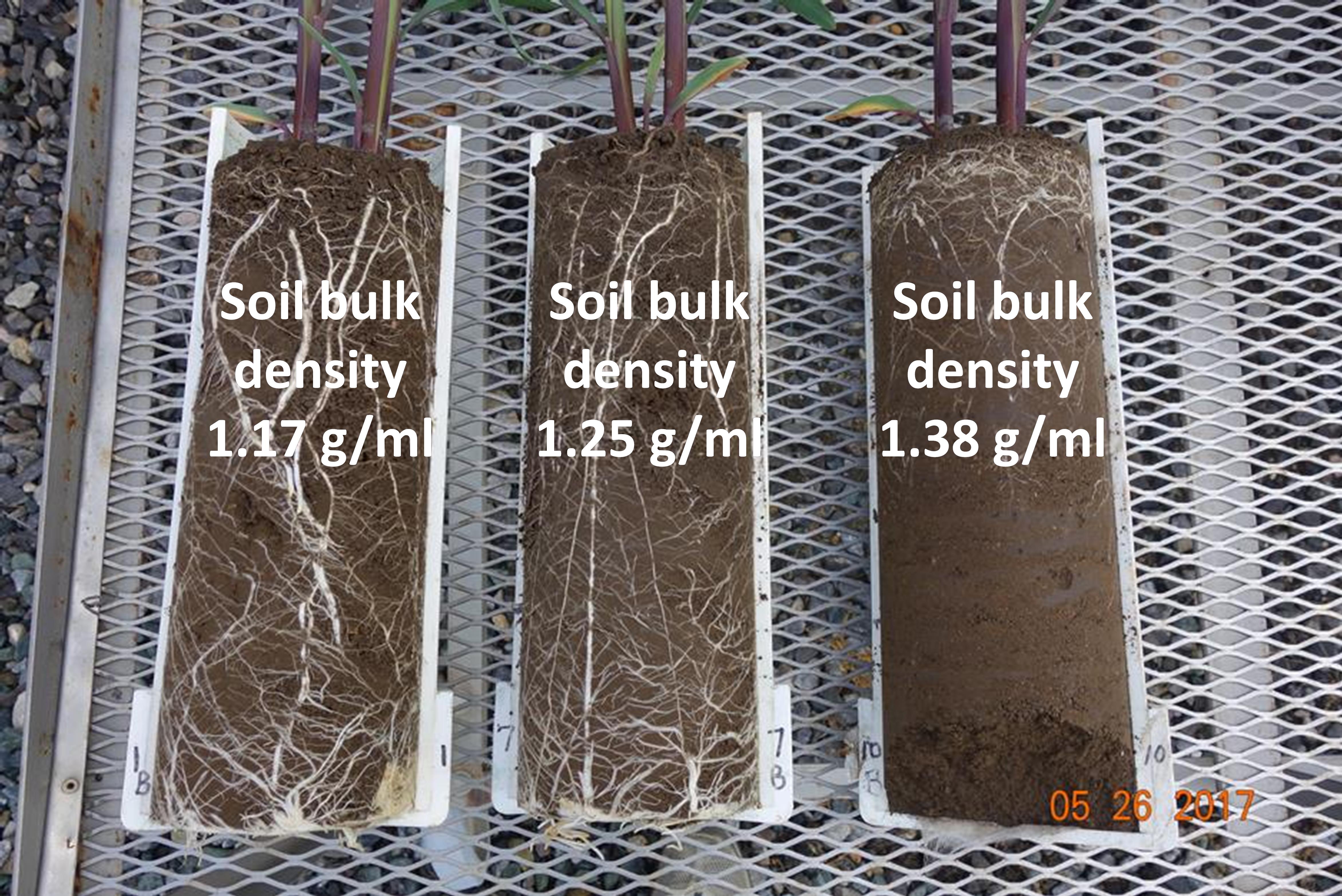

The primary negative effect of soil compaction on crop production is a reduction in the ability of soil to supply water and nutrients to the crop. There are multiple aspects of compaction that contribute to this outcome. Compacted soils limit the ability of plant roots to grow into new soil to extract water and nutrients, effectively reducing the amount of the soil profile that is available to contribute to supplying water and nutrients for crop growth (Figure 3). The reduction in pore space in the soil also reduces the overall water holding capacity of the soil, meaning less water is available for plant uptake.

Figure 3. Root growth of corn plants (V5 growth stage) growing in soil compacted to different bulk densities before corn seeds were planted (Strachan and Jeschke 2017).

Compaction reduces the rate at which water moves downward through the soil profile (Figure 4). This lower rate of infiltration can reduce the proportion of water from a rainfall event that penetrates the soil and becomes available for crop uptake and increase the proportion lost to runoff. Increased runoff can have the additional negative effect of greater risk of soil erosion

Figure 4. Water, as it drains through the soil profile, is limited by a zone of highly compacted soil (outlined by the red box). Water drains through less compacted soil more quickly and eventually begins to move below the zone of high compaction (Strachan and Jeschke 2017).

Reduced infiltration rate also means that, once saturated, compacted soils are slower to drain. This can negatively affect crop growth by reducing the availability of oxygen to plant roots needed for proper growth. Slower drainage can also reduce the rate at which soils warm up in the spring and increase the amount of time after a rainfall event needed for the soil to dry out and become suitable for field work.

Soil moisture is the most important factor influencing the risk of soil compaction (Soane and Van Ouwerkerk, 1994). Drier soils can sustain heavier loads without becoming compacted. Soils with moisture levels at or above field capacity have the greatest potential for compaction. Water acts as a lubricant between soil particles that allows soil to be pushed together. As more air space is replaced with water, the potential for compaction increases, up to a maximum point referred to as the “plastic limit.” At soil saturation levels above this point, the compactive potential of the topsoil declines since water cannot be compressed. However, this results in the compactive force being directly transferred to the subsoil, increasing the risk of subsoil compaction (Duiker, 2004). Additionally, trafficking very wet soils often results in extensive smearing of the topsoil, which reduces hydraulic conductivity and may be even more detrimental to crop root growth than compaction (Raper and Kirby, 2006).

There are some simple in-field tests that can be used to make

a rough determination if the soil is too wet to work without a high risk of compaction. One such test is the “ribbon test,” which involves digging down 4 inches into the seed bed, grasping a handful of soil, and squeezing it tightly in your hand. If the soil forms a “ribbon” when squeezed between the thumb and forefinger, it is in a condition for compaction to occur (Figure 5).

Figure 5. The “ribbon test” can be used to assess soil moisture and determine if soil is at high risk for compaction.

Soil texture (% of sand, silt and clay in a soil) has some effect on compaction potential. Soils that consist of particles of equal size have less compactive potential than soils that have particles of varying sizes. Smaller particles can fill spaces between larger particles, thereby increasing soil density. A sandy loam soil is the most susceptible to compaction, while pure sands, clays, and silt soils are least. Soil texture can also influence the pattern of compaction in the soil. Compaction in coarser soils tends to penetrate vertically downward into the soil profile, while in finer texture soils compaction tends to penetrate downward and outward laterally in the soil profile (Ellies Sch et al., 2000).

Compaction potential is also influenced by soil structure. Natural processes in the soil, including wetting and drying, freezing and thawing, and bacterial, fungal, and root growth result in the formation of aggregates. Aggregates are groups of soil particles that bind more tightly to each other than to adjacent particles. Collectively, the stability of these aggregates is referred to as soil structure. Soil structure provides an important defense against soil compaction. Without good structure, individual soil particles are more susceptible to compaction from external pressure. Soils higher in organic matter generally have better soil structure and resist compaction better than low organic matter soils.

Tillage, falling rain, and compaction are the primary mechanisms by which soil aggregates are destroyed. Tillage operations that combine shearing action with substantial down pressure cause the most damage to soil structure due to the destruction of soil aggregates and the tendency to form a tillage pan at the bottom of the plow layer. Compaction from heavy loads applied to the soil can be both a cause and consequence of poor soil structure. Compaction can cause granular structure in the topsoil to break down and reform as blocky or platy structure.

There are a number of different forms of soil compaction that can occur in crop production and negatively affect crop growth and yield. Some forms of compaction, such as surface crusting and sidewall compaction, can significantly reduce yield under certain conditions but are generally less of a management concern due to the fact that the compaction generally does not persist in the soil for very long and there are various management options available to prevent or mitigate their effects. Other forms of compaction, such as tillage pans and subsoil compaction, can persist for years and are much more challenging to manage.

Surface crusting is a form of soil compaction that reduces seed emergence and water infiltration rates. It is caused by the impact of raindrops on surface soil particles. Heavy impact causes soil particles to sift together. Rapid soil drying increases potential of surface crusting. Soils with higher organic matter or sand content have less potential for crusts to form. Reduced- and no-tillage systems are generally at lower risk of surface crusting due to better soil structure and greater amounts of crop residue on the soil surface. Rotary hoes can be used to break up crusts and improve emergence and stand establishment.

Sidewall compaction typically results from planting into soils that are too wet and/or applying too much down pressure on the row units. The action of the planting disc openers shearing into wet soils can cause seed furrow sidewalls to become hard after planting (Figure 6). The result can be poor crop emergence and poor root development out of the seed furrow. The consequences of restricted root development can be magnified if conditions turn drier and the crop encounters drought stress later in the season. Severe sidewall compaction reduced corn yield by 50% in a University of Kentucky Extension demonstration (Lee, 2011). The use of spiked closing wheels may help reduce sidewall compaction by tilling in the soil around the seed and breaking up the sheared sidewall face, but is unlikely to completely eliminate its effects.

Figure 6. Left: Compaction of the seed furrow sidewall due to double-disk openers slicing through the soil in wet seedbed conditions. Right: Corn roots showing the effects of sidewall compaction due to wet field conditions at planting.

Topsoil compaction occurs from the soil surface down through the normal tillage zone. This type of compaction is typically caused by wheel traffic or animal traffic. Effects of topsoil compaction on crops can vary depending on weather conditions and are generally worse in wet growing seasons. Topsoil compaction is usually temporary and can be partially remediated by normal tillage. Natural processes such as freeze-thaw cycles, wet-dry cycles, microbial activity and plant root growth will also tend to alleviate topsoil compaction over time and rebuild soil structure.

A tillage pan is a layer of subsoil compaction only a few inches thick right beneath the normal tillage zone. This type of compaction is caused by repeated tilling at the same depth, particularly with tillage implements that shear and compress the soil at the bottom of the plow layer, such as discs, moldboard plows, and sweep type implements. Deep tillage may help break up tillage pans under certain conditions but can also make the problem worse if the soil is too wet or is immediately recompacted.

Deep compaction lies beneath the tillage zone and is caused by high axle weight loads applied to the soil. Harvest equipment such as grain carts and combines have high axle loads, and most often are the biggest contributors to deep compaction. Heavy loads can compact soil more than two feet down into the soil profile. Deep compaction is the most difficult to eliminate and can negatively affect crop growth and yield for years after the compaction took place, so prevention is important.

Soil compaction can result in malformed root growth, including stubby, flat, thin, or twisted roots. Roots growing into a tillage pan can grow horizontal rather than vertical and will have flat, shallow root systems. Above ground growth is directly related to below ground root growth. If root growth is being impaired, vegetative growth above ground will likely be stunted.

Look for specific patterns or areas in field such as wheel track patterns, particularly wheel tracks associated with very heavy loads such as combines, grain carts, or liquid manure spreaders (Figure 7). In some cases, a specific pattern is not visible. These areas can result from repeated overlapping of the same areas with different tillage passes that, over time, have an additive effect on areas within the field.

Nutrient stresses on crops can be another sign of compaction. Since roots are the avenues of soil nutrients to the crop, root restrictions can decrease interception of nutrients in the soil. Phosphorous, potassium and nitrogen deficiencies can be secondary symptoms of soil compaction.

Figure 7. Corn field with uneven emergence due to compaction in wheel tracks. Photo: Jim Boersma.

Standing water or excessive water erosion can be caused by soil compaction. Compaction reduces pore space within soil so water is not absorbed into soils as readily. Increased power requirements for field operations can be a sign of compaction as well. If field tillage operations encounter certain areas in a field where the tractor “pulls down” this can signal a compacted area.

Sidewall, surface crusting, and tillage pan compaction are the easiest forms to detect with a shovel or other type of digging device. Deep soil compaction is harder to find since it occurs deeper in the soil.

Cone tipped penetrometers can be used to locate compaction (Figure 8). These have limitations however. Penetration resistance is a function of soil density and moisture content. Compacted and non-compacted soils of equal moisture and texture need to be compared. Therefore, there is no specific numerical value of resistance (psi) that identifies compaction. Comparative values need to be evaluated (Duiker, 2002). Constant rates of push also must be maintained to give accurate readings. Motor drive penetrometers, which penetrate the soil at a fixed rate, give the most accurate readings.

Figure 8. Measuring soil compaction with a soil penetrometer.

Soil probes are another useful tool. These are also subject to moisture content and soil density. A drier soil will probe harder than a wet soil; clays will probe harder than loam soils for instance. Soil probes can be used effectively to monitor differences in the soil moisture profile. If the top foot of soil is extremely dry, but second foot is very moist, this suggests that crop’s roots are not penetrating into the second foot, possibly because of compaction

The best indicator of compaction is viewing root growth patterns into the soil profile. This is accomplished by using a spade or shovel to dig holes or trenches alongside the existing crop. Holes should be dug alongside the existing crop in suspected compaction areas.

Brady, N. C. 1990. The nature and properties of soils, 10th ed. pp. 91-152. MacMillan Publishing Co., New York.

Duiker, S. 2002. Diagnosing Soil Compaction Using a Penetrometer (soil compaction tester). Penn State Univ. Ext. https://extension.psu.edu/downloadable/download/sample/sample_id/586/

Duiker, S. 2004. Avoiding Soil Compaction. Penn State Univ. Ext. https://extension.psu.edu/avoiding-soil-compaction

Ellies Sch, A., R.R. Smith, F.J. Jose Dorner, and T.A. Proschle. 2000. Effect of moisture and transit frequency on stress distribution on different soils. Agro Sur. 28:60-68.

Lee, C. 2011. Sidewall Compaction Early Hurts Yields Late. University of Kentucky Extension. Grain Crops Update August 16, 2011.

https://graincrops.blogspot.com/2011/08/sidewall-compaction-early-hurts-yields.html

Raper, R.L., and J.M. Kirby. 2006. Soil Compaction: How to Do It, Undo It, or Avoid Doing It. ASAE Distinguished Lecture #30, pp. 1-14. Agricultural Equipment Technology Conference. ASABE Publication Number 913C0106.

Soane, B.D., and Van Ouwerkerk, C. (Eds.), 1994. Soil Compaction in Crop Production, Developments in Agricultural Engineering Series, vol. 11. Elsevier Science, Amsterdam, The Netherlands, pp. 662.

Strachan, S.D., and M. Jeschke. 2017. Water Retention and Nutrient Availability in Soil: Drainage and Compaction. Pioneer Crop Insights, Vol. 27, No. 11. https://www.pioneer.com/home/site/us/agronomy/soil-water-retention-nutrient-availability/

USDA-NRCS. 2008. Soil Quality Indicators – Bulk Density. https://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs142p2_053256.pdf

Wolkowski, R. 2010. Addressing the Soil Compaction Problem. University of Wisc. Extension. http://www.soils.wisc.edu/extension/materials/Diagnosing_Compaction.pdf

1Pioneer Agronomy Manager

2Pioneer Agronomy Sciences Intern

The foregoing is provided for informational use only. Please contact your Pioneer sales professional for information and suggestions specific to your operation. Product performance is variable and depends on many factors such as moisture and heat stress, soil type, management practices and environmental stress as well as disease and pest pressures. Individual results may vary.

October 2018