Planting Outcome Effects on Corn Yield

Authors: Tom Doerge, Mark Jeschke, and Paul Carter, Ph. D

Authors: Tom Doerge, Mark Jeschke, and Paul Carter, Ph. D

Planning and execution associated with corn planting are critical if growers are to maximize the genetic potential of today’s elite corn hybrids. The simple secret for success is to “do everything right.” Many of these key management decisions are made well before the planting season, including choice of hybrid, crop rotation, tillage system, nutrient placement, target planting rate, and row spacing.

This Crop Insights will focus on the four planting outcomes that are achieved during planting itself. The relative impacts these four factors have on grain yield were recently summarized by Dr. Jeff Coulter from the University of Minnesota4 and are presented below.

These goals and their estimated typical impact on yield include:

The latest research related to achieving each of these four planting outcomes will be discussed and, in several cases, suggest the need to rethink conventional wisdom regarding their importance in affecting grain yield.

A primary goal of corn growers is to achieve stands containing uniformly large-sized plants that consistently produce one full-sized ear each. Small, delayed, or “runt” plants rarely, if ever, produce full-sized ears. Traditionally, growers have assumed that the primary cause of these smaller, undesirable plants was a delay in the time of emergence. And often the cause for delayed emergence was assumed to be inconsistent seeding depth. Logically, late-emerging plants are less able to compete for limited light, nutrient, and moisture resources with earlier-emerging, larger neighbors. Several studies have indeed documented significant yield loss when the development of plants within the stand was delayed (Nafziger et al., 1991; Ford and Hicks, 1992; Liu et al., 2004a, 2004c). These studies typically used multiple planting dates 7 - 28 days apart to achieve varying degrees of delayed plant growth. These

studies are valuable in demonstrating certain aspects of plant-to-plant competition and give some guidance for making replant decisions. But they are of little value in understanding the effects of time of emergence on individual plant yield in stands planted all on the same day, as is typical in commercial corn production. They also do not indicate the relative importance of time of emergence versus other factors occurring after stand establishment or how final plant yield is impacted by each.

There is widespread agreement that large plants exhibiting well-synchronized silk emergence and pollen shed produce the largest and most consistent-sized ears (Pagano et al., 2007; Kovács and Vyn, 2014). However, these studies have also shown that time of emergence has relatively little effect on plant biomass and final grain yield. In a 2-year study in Indiana, Murua (2002) documented that time of emergence in conventionally-planted corn stands only explained about 4% of the variation in individual plant yield. A similar study by Kovács and Vyn (2014) found that value to be only about 1%.

Other studies from Argentina found that even when corn canopies emerge uniformly, they can develop well-established plant hierarchies as early as the V4 growth stage (Pagano et al., 2007; Maddonni and Otegui, 2004). These differences in plant size within the stand are probably explained by “other” factors such as moisture availability, compaction, soil textural differences, nutrient acquisition, or insect damage and clearly not time of emergence. The notion that a plant emerging more than 48 hours after its neighbors is a “weed” is clearly not supported by these studies. In fact, Kovács and Vyn (2014) further warn, “the importance of ultra-uniform seedling emergence times for adjacent plants within the row can easily be overstated.”

Determining the exact effect of uniform emergence is difficult, in part because studies have used different ways to measure and express emergence uniformity. Some of the different measures used include calendar or growing degree days from planting to emergence, time to 50% emergence, number of leaf stage growth differences, and days of emergence delay after the mean emergence date of the plant stand. Ford and Hicks (1992) measured a 6% yield loss when every second plant had a 1-leaf stage delay and a 5% yield loss when every sixth plant had a 2-leaf delay. Liu et al. (2004a, 2004c) found that yield decreased 2% per day whenever the time to 50% emergence was delayed by more than 3 days. Nishikawa and Kudo (1973) report that per plant yield declines by 5% for every day in emergence delay after the mean emergence date of the plant stand. And finally, Murua (2002) measured an average of 2.3% yield loss for every additional day’s delay in emergence of individual plants.

These results suggest that delays in emergence can result in average yield losses in the 5 - 9% range proposed by Coulter. Careful attention to managing planting depth, seed trench compaction, surface crusting, seed furrow closure, and surface residue will minimize these yield losses. But beyond that, attention to other factors, such as uniform moisture, nutrient availability, soil compaction and disease and insect protection, may be even more important in achieving uniform stands at physiological maturity with low plant-to-plant variability in ear size and maximum grain yield.

Timely planting of full-season hybrids allows the corn crop to take full advantage of the available growing season. Numerous studies have shown that corn yield potential declines as planting is delayed beyond the optimum planting window for a given geography (Coulter, 2012; Farnham, 2001; Myers and Wiebold, 2013; Nafziger, 2008).

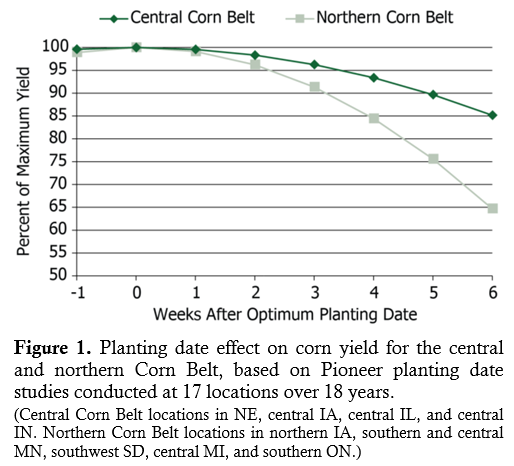

Results from Pioneer planting date studies conducted over 18 growing seasons show that yield was maximized when corn was planted within the two-week period around the optimum planting date (Jeschke and Paszkiewicz, 2013). The optimum planting date was April 16 for the central Corn Belt and April 30 for the northern Corn Belt. Yield declined for planting dates following the optimum window, and the rate of yield decline increased with delay duration. The yield penalty associated with delayed planting was greater in the northern Corn Belt where the growing season is shorter. Yield of corn planted four weeks following the optimum date was reduced by 7% in the central Corn Belt, compared to over 15% in the northern Corn Belt (Figure 1).

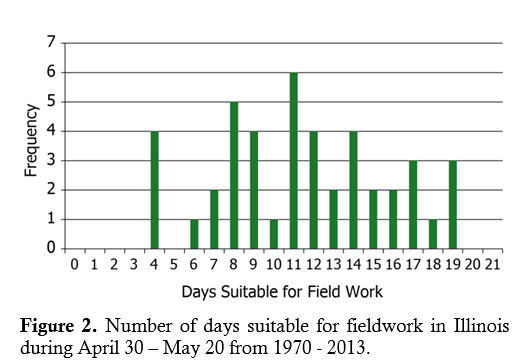

The ability to get corn planted within the optimum planting window is largely driven by weather conditions during this time. The number of suitable days can vary greatly from year to year. For example, an analysis of USDA data by Irwin and Good (2014) showed that the number of days suitable for fieldwork in Illinois from 1970-2013 during the three weeks spanning April 30 - May 20 ranged from as many as 19 to as few as 4 across these years (Figure 2). On average, slightly over half (11.5) of the days in the three-week period were suitable for field work.

It is commonly believed that larger planters and improved technology have increased the pace at which the U.S. corn crop can be planted, although examinations of USDA planting data have shown this is not actually the case (Irwin and Good, 2011; Kucharik, 2006). Although larger planters have enabled a single operator to cover more acres in a day than was possible in the past, the total number of planters in use has declined as farm operations have consolidated. Planting data show that, in general, the U.S. corn crop is planted much earlier now than it was 30 years ago; however, the pace at which it is planted has not accelerated, and weather is the primary factor that determines planting progress. Since yield losses only occur on acres planted fol-lowing the optimum window, typical farm-wide yield losses due to planting delays likely average no more than 2-5%.

Unlike planting timing, which is often heavily influenced by weather conditions, plant population is a yield determining factor largely within the control of the grower. However, determining and achieving the ideal population to maximize yield is complicated, as the optimum population in a given situation can be influenced by a number of factors, such as yield level, hybrid, and weather conditions.

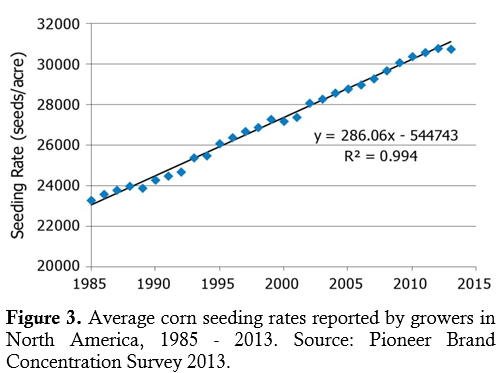

In general, optimum populations for corn have steadily increased over time. Higher populations accompanied by improved stress tolerance in hybrids have contributed to incremental yield gains. Average corn seeding rates used by growers in the U.S. and Canada have increased from about 23,000 seeds/acre in 1985 to over 30,000 seeds/acre today, or approximately 300 seeds/acre per year (Figure 3).

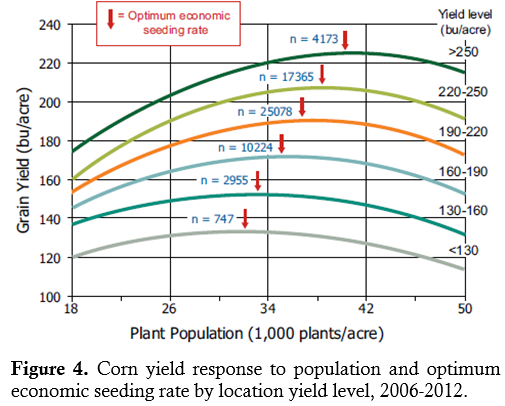

Yield level: Pioneer and university studies have shown that corn hybrid response to plant population varies by yield level. The population required to maximize yield increases as yield level increases. When grouped by yield level, results from Pioneer plant population trials showed that the economic optimum seeding rate increased from approximately 27,000 seeds/acre at yield levels below 130 bu/acre to over 38,000 seeds/acre at yield levels above 250 bu/acre (Figure 4). An Iowa State University study comparing corn yield response to plant population across soils with different corn suitability ratings found similar results. The most productive soils tended to have a higher optimum population for maximum yield (Woli et al., 2014).

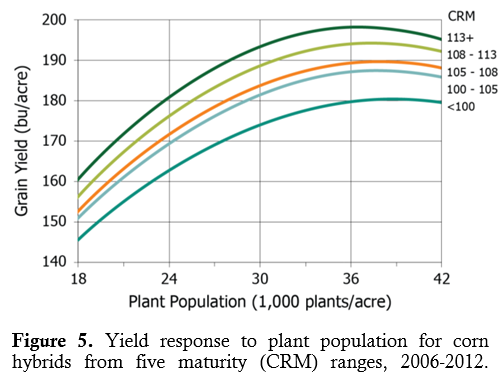

Hybrid maturity: Research has shown that early maturity hybrids (<100 CRM) may require higher populations to maximize yield. Figure 5 shows the yield response of hybrids to plant population grouped by CRM range in Pioneer trials conducted from 2006-2012.

Although this trend can still be detected when examining the response curves closely, it is a smaller difference than in the past. This change may be the result of different genetic backgrounds predominant in early maturities historically vs. currently, or other unknown factors.

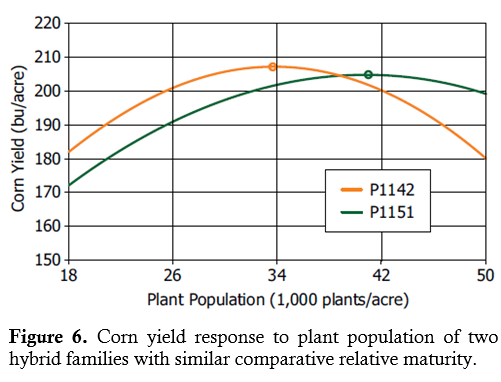

Hybrid genetics: Yield response to plant population can also vary based on hybrid genetics. Figure 6 shows an example of two hybrid families with the same CRM that have been shown to differ in their response to plant population in Pioneer research trials. One hybrid family (Pioneer® hybrid P1142) has a plant population response that is typical of current 111 CRM hybrids, whereas the other (Pioneer® hybrid P1151) tends to achieve maximum yield at higher plant populations. Pioneer offers growers an online planting rate calculator that provides recommendations based on a selected hybrid, grain price, seed cost, and yield level.

A plant population that is too high or too low can negatively impact yield. A low population may limit yield potential when growing conditions are favorable, while a high population may result in reduced performance and standability under stress conditions. In general however, modern hybrids tend to have a relatively wide margin of error when it comes to ideal population. For example, both of the hybrid families shown in Figure 6 could be as much as 4,000 plants/acre over or under the optimum population and still have less than 2 bu/acre variation in yield.

One reason for this is the improvements in stress tolerance that have resulted from decades of targeted breeding. A common stress response of older corn hybrids was “barrenness,” or the inability to produce an ear. Even as recently as 30 years ago, some of the best hybrids were prone to barrenness when population thresholds were exceeded. Modern corn hybrids are better able to produce an ear under moisture and density stress, even though ears are progressively smaller under increasing stress. This means that when plant density optimums are exceeded, yields tend to level off rather than drop abruptly. This hybrid characteristic has changed the risk/reward equation in the grower’s favor. Because the risk that excess populations will decrease yields under dry conditions is reduced, growers can more confidently plant higher populations that support increased yields when favorable conditions develop.

Growers instinctively prefer corn stands with uniform plant-to-plant spacing. A “picket-fence” stand is both aesthetically pleasing and presumably higher yielding.

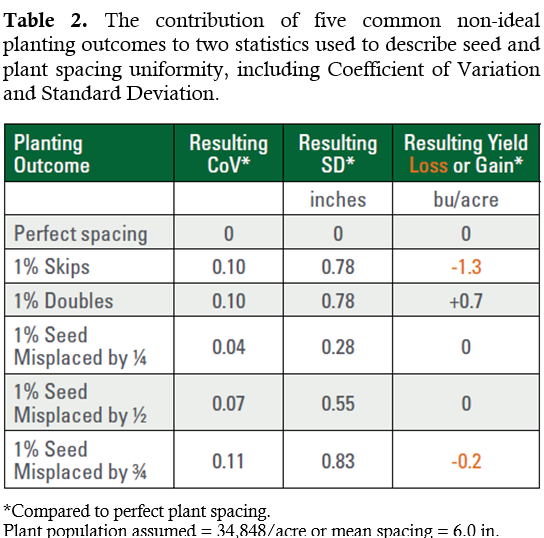

Seeding specialists and agronomists have long used two related statistics, coefficient of variation (CoV) and standard deviation (SD), as the preferred metrics to quantify meter performance and plant spacing uniformity. A SD value of 2.0 inches or the corresponding CoV value of 0.33 are widely cited as the thresholds above which corn yield loss would be expected (Nielsen, 2001). The CoV is easily calculated by dividing the SD by the average plant spacing. For example, the SD corresponding to a CoV of 0.33 at an average spacing of 6.0 inches is 2.0 inches. More recently, engineers have also devised a “singulation” metric as an indicator of seed spacing uniformity, although there is no industry standard as to how it is calculated.

Agronomists have long known that the various planting outcomes that result in increasing CoV and SD and declining singulation values can have widely different impacts on resulting individual-plant grain yield (Nafziger, 1996; Doerge et al., 2002; Nafziger, 2006). Thus, the use of easy-to-measure plant spacing metrics that are poorly correlated with individual plant yields has, unfortunately, created a tradeoff between convenience and accuracy. This has no doubt contributed to inconsistent results in past research seeking to explain the impact of within-row plant spacing on corn grain yield (Krall, 1977; Nafziger, 1996; Nielsen, 2001; Doerge and Hall, 2000; Doerge et al., 2002; Lauer and Rankin, 2004; Liu et al., 2004a, 2004b, 2004c; Nielsen, 2006).

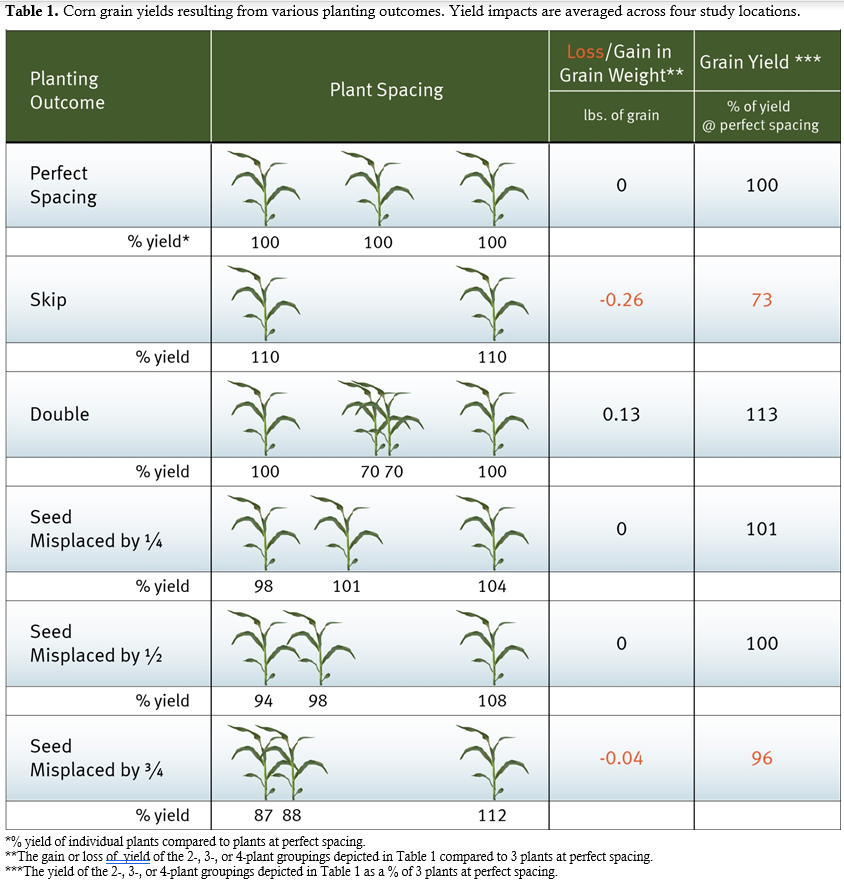

A 2002 Pioneer study (Doerge et al.) uniquely allows for quantifying the impacts of common and realistic non-ideal planting outcomes on grain yield. This study was conducted in four different environments (two in Iowa, one in Missouri, and one in Minnesota), across a wide yield range of 109 to 206 bu/acre, and using hybrids with three very different genetic pedigrees. In this study, within-row spacing measurements and grain yields were determined on >6,000 individual plants.

There are several explanations for the lack of agreement in the results from past plant spacing studies, which were all conducted by highly-qualified researchers. First of all, different planting outcomes that contribute to SD, CoV, or singulation can have completely different effects on individual plant yield (Table 2). Skips are highly detrimental to yield, doubles can be slightly positive, and misplaced plants have no effect on yield until plants are displaced from their preferred location by more than half the normal plant-to-plant distance. Second, no two fields can be expected to have the same amount or combination of non-ideal planting outcomes. Thus, it is no wonder that comparisons from aggregated, plot- or field-wide plant spacing studies are contradictory if the sources of plant spacing non-uniformity are not considered. Unfortunately, this lack of consideration has been true of most plant spacing studies.

Other sources of confounding include the manner in which some field experiments have been conducted. For example, some studies have used highly artificial groupings of plants to achieve pre-determined levels of plant spacing variability. In addition to being unrepresentative of “real-world” conditions, they often employ only different levels of misplaced plants (no skips or doubles) to achieve the desired spacing treatments. Tables 1 and 2 indicate that these types of plant arrangements will have little to no impact on yield. Other plant spacing studies may have been compromised by the use of overplanting and thinning to achieve the desired plant spacing arrangements and populations. These practices are potentially confounding because corn plants can sense the presence of neighboring plants beginning very shortly after emergence due to subtle differences in the ratios of red: far red light they receive (Liu et al., 2009). These light quality differences can act as an early signal of pending competition that can initiate a shade avoidance response in the remaining plants. Thus overplanting and thinning can unintentionally result in plants that have been pre-conditioned to exhibit less favorable crop architecture and lower grain yield potential.

In contrast, when individual plant yields arising from different planting outcomes are considered, research results have been amazingly consistent. For example, Nafziger (1996) found that 10% skips in four Illinois experiments resulted in an average 8.1% decrease in yield (at 30,000 plants/acre) while the findings from the Pioneer study (Doerge et al., 2002) measured a corresponding 8.9% yield decrease (at a similar plant population). Likewise, the Illinois studies measured a yield increase of 4.2% for 10% doubles while the Pioneer data revealed a 4.7% yield increase. These similarities are notable since the genetics used in these two sets of experiments were released at least a decade apart.

Clearly, the key messages on within-row plant spacing uniformity are: 1) it does impact grain yield and can be explained, 2) whole-field impacts on grain yield are usually relatively small, averaging about 1 to 2%, and 3) growers should work to minimize or eliminate skips and not worry about occasional doubles or slightly misplaced plants.

Coulter, J. 2012. Planting Date Considerations for Corn. Minnesota Crop News. Univ. Of Minnesota Extension.

Doerge, T.A., Hall, T. and Gardner, D. 2002. New research confirms benefits of improved plant spacing. Crop Insights, Vol. 12, No. 2. Pioneer.

Doerge, T.A. and Hall, T. 2000. The value of planter calibration using the MeterMax™ system. Crop Insights, Vol. 10, No. 23. Pioneer.

Farnham, D. 2001. Corn Planting Guide. Iowa State Univ. Extension. PM 1885.

Ford, J.H. and D.R. Hicks. 1992. Corn growth and yield in uneven emerging stands. J. of Production Agriculture, 5:185-188.

Kovács, P. and T.J. Vyn. 2014. Full-season retrospectives on causes of plant-to-plant variability in maize grain yield response to nitrogen and tillage. Agron. J. 106:1746-1757.

Krall, J.M., Esechie, H.A., Raney, R.J., Clark, S., and Vanderlip, R.L. 1977. Influence of within-row variability in plant spacing on corn grain yield. Agron. J. 69:797-799.

Kucharik, C.J. 2006. A multidecadal trend of earlier corn planting in the Central USA. Agron. J. 98:1544-1550.

Lauer, J. and Rankin, M. 2004. Corn response to within row plant spacing variation. Agron. J. 96:1464-1468.

Liu, J.G., Mahoney, K.J., Sikkema, P.H. and Swanton, C.J. 2009. The importance of light quality in crop-weed competition. Weed Research, 49:217-224.

Liu, W., Tollenaar, M., Stewart, G. and Deen, W. 2004a. Impact of planter type, planting speed and tillage on stand uniformity and yield of corn. Agron. J. 96:1668-1672.

Liu, W., Tollenaar, M., Stewart, G. and Deen, W. 2004b. Within-row plant spacing variability does not affect corn yield. Agron. J. 96:275-280.

Liu, W., Tollenaar, M., Stewart, G. and Deen, W. 2004c. Response of corn grain yield to spatial and temporal variability in emergence. Crop Sci. 44:847-854.

Maddonni, G.A. and Otegui, M.E., 2004. Intra-specific competition in maize: early establishment of hierarchies among plants affects final kernel set. Field Crops Res. Vol. 85:1-13.

Nafziger, E.D., P.R. Carter, and E.E. Graham. 1991. Response of corn to uneven emergence. Crop Sci. 31:811-815.

Nafziger, E.D. 1996. Effects of missing and two-plant hills on corn grain yield. J. Prod. Agric., 9:238-240.

Nafziger, E.D. 2006. Inter- and intraplant competition in corn. Plant Management Network. Online. Crop Management doi:10:.1094/CM-2006-0227-05-RV.

Nishikawa, H. and Kudo, M. 1973. Explanation of the appearance of a sterile ear on mechanically cultivated corn (zea mays, L.). Res. Report Tohoku Agric. Expt. Stn. 51-95.

Pagano, E. , Cela, S., Maddonni, G.A., and Otegui, M.E., 2007. Intra-specific competition in maize: Ear development, flowering dynamics and kernel set of early-established plant hierarchies. Field Crops Res. Vol. 102:198-209.

Woli, K.P., C.L. Burras, L.J. Abendroth, and R.W. Elmore. 2014. Optimizing corn seeding rates using a field’s corn suitability rating. Agron. J. 106:1523-1532.

Authors:

The foregoing is provided for informational use only. Please contact your Pioneer sales professional for information and suggestions specific to your operation. Product performance is variable and depends on many factors such as moisture and heat stress, soil type, management practices and environmental stress as well as disease and pest pressures. Individual results may vary.

January 2015