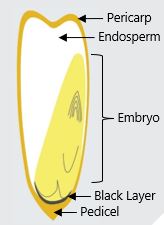

- Black layer is often used as a visual indicator of physiological maturity and the two are often considered synonymous, but this is not actually the case.

- Black layer formation is triggered when sucrose trans-location to the developing kernel stops.

- This cessation of sucrose flow can be due to the physiological maturity of the kernel but can also be the result by other factors causing a sharp drop in plant photosynthesis such as foliar disease, hail, frost, or prolonged cold temperatures.

- Black layer formation triggered by environmental stress can occur before physiological maturity, effectively shutting down grain fill prematurely.

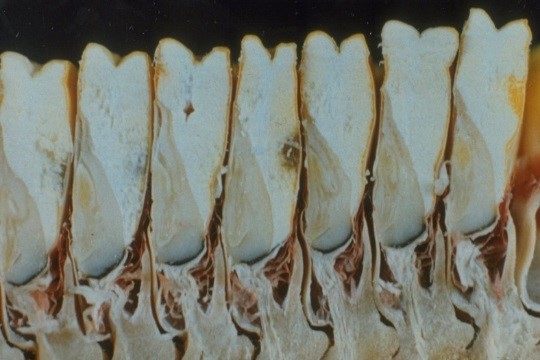

Cross section of kernels following physiological maturity. The black abscission layer is visible at the tip of the kernels.

Dry Down Following Maturity

- Kernel drying that occurs following black layer is entirely due to evaporative moisture loss.

- Corn dry down rate is tightly linked to daily growing degree unit (GDU) accumulation.

- In general, drying corn from 30% down to 25% moisture requires about 30 GDUs per point.

- Drying from 25% to 20% requires about 45 GDUs per point (Lauer, 2016).

- GDU accumulation and dry down rates are greatest during the earlier, warmer part of the harvest season and decline as the weather gets colder (Table 2 and 3).

- By November, GDU accumulation rates are low enough that little further drying will typically occur.

Table 2. Average daily GDU accumulation during early-, mid-, and late-September and October for several Midwestern locations (1981-2010 average, Midwest Regional Climate Center).

| |

September

|

October

|

| |

1-10

|

11-20

|

21-30

|

1-10

|

11-20

|

21-31

|

Lincoln, NE

|

20

|

17

|

14

|

11

|

8

|

7

|

Indianapolis, IN

|

20

|

16

|

13

|

11

|

8

|

6

|

Bloomington, IL

|

20

|

17

|

13

|

12

|

8

|

6

|

Ames, IA

|

18

|

14

|

12

|

10

|

7

|

5

|

Mankato, MN

|

17

|

13

|

10

|

8

|

6

|

4

|

Madison, WI

|

16

|

14

|

11

|

9

|

6

|

4

|

Brookings, SD

|

15

|

12

|

9

|

7

|

5

|

3

|

Table 3. Average daily corn dry down rate for difference stages of the harvest season (Hicks, 2004).

Harvest Season Stage

|

Points of Moisture per Day

|

Sept. 15 – Sept. 25

|

¾ to 1

|

Sept. 26 – Oct. 5

|

½ to ¾

|

Oct. 6 – Oct. 15

|

¼ to ½

|

Oct. 16 – Oct. 31

|

0 to ⅓

|

Nov. 1 and later

|

~0

|

Timing of Physiological Maturity

- Corn that matures earlier will dry down faster due to more favorable drying conditions early in the harvest season.

- Later maturing corn has fewer warm days to aid in drying, and will dry down at a slower rate.

Weather Conditions Following Maturity

- Daily GDU accumulation and dry down can vary widely during the harvest season.

- Corn may dry 1 point of moisture per day or more under favorable conditions.

- Conversely, corn may not dry at all on a cool, rainy day.

Hybrid Characteristics Affecting Dry Down

Husk leaf coverage – The more insulated the ear is, the longer it will take to dry down. Leaf number, thickness, and tightness all affect dry down rate.

Husk leaf senescence – the sooner these leaves die, the faster the grain will dry down.

Ear angle – Upright ears are more prone to capture moisture in the husks which slows dry down.

Kernel pericarp characteristics – Thinner or more permeable pericarp layers are associated with a faster dry down rate.

References

Abendroth, L.J., R.W. Elmore, M.J. Boyer, and S.K. Marlay. 2011. Corn Growth and Development. PMR 1009. Iowa State University Extension, Ames, Iowa.

Hicks, D.R. 2004. The Corn Crop – Frost and Maturity. Univ. of Minnesota.

Lauer, J. 2016. Corn Harvesting. Univ. of Wisconsin-Madison Extension, Madison, Wisconsin.

Author: Mark Jeschke

Vol. 11 No. 35 August 2019

The foregoing is provided for informational use only. Please contact your Pioneer sales professional for information and suggestions specific to your operation. Product performance is variable and depends on many factors such as moisture and heat stress, soil type, management practices and environmental stress as well as disease and pest pressures. Individual results may vary.